A customer connected online to our Remote service with a second-generation Smart ForTwo W451, reporting, “The car shifts slowly or not at all.” Our immediate focus shifted to the gearbox. The second-generation Smart ForTwo employs a five-speed automated gearbox manufactured by Getrag, known as the 5AMT130 model, featuring a “Sprintsift” Transmission Control Module (TCU).

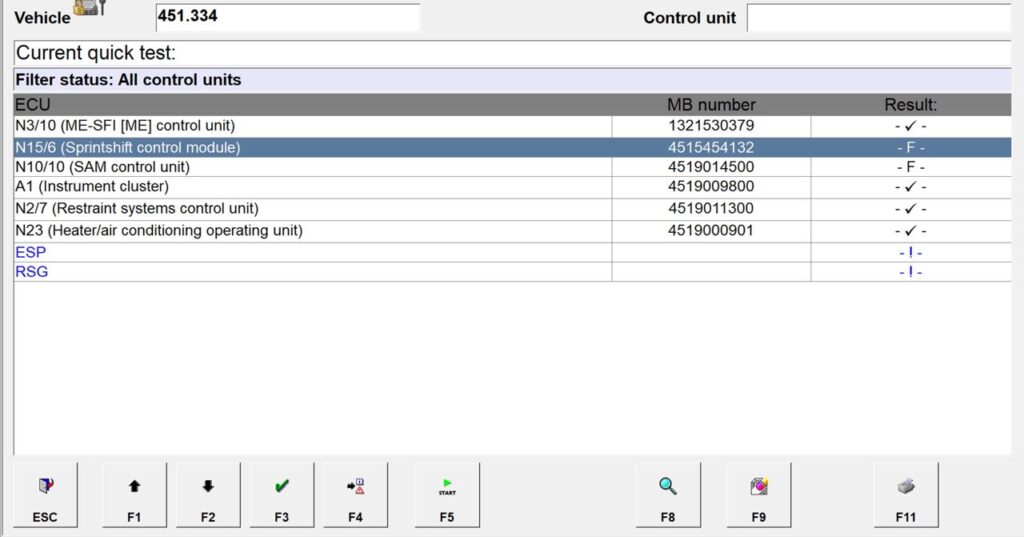

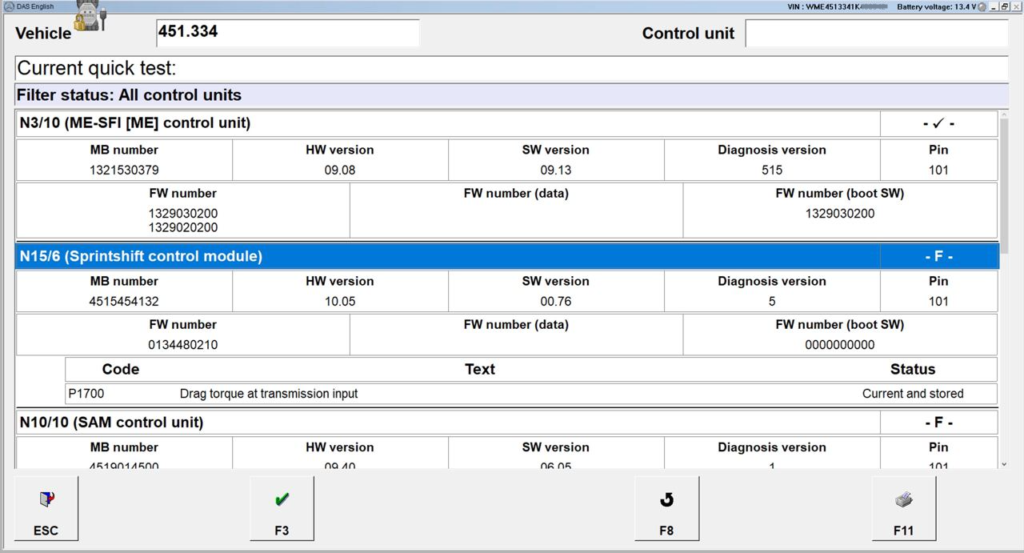

Following the intake scan, the following observations come to light:

In Smart vehicles, encountering error code P1700 (Drag torque* at transmission input) is frequent. This code isn’t only linked to the mechanical aspects of the gearbox but also to the Sprintshift control module (TCU). When this code appears, the car may continue to operate, but shifting might be slower than usual or fail entirely, often triggering a dashboard warning message.

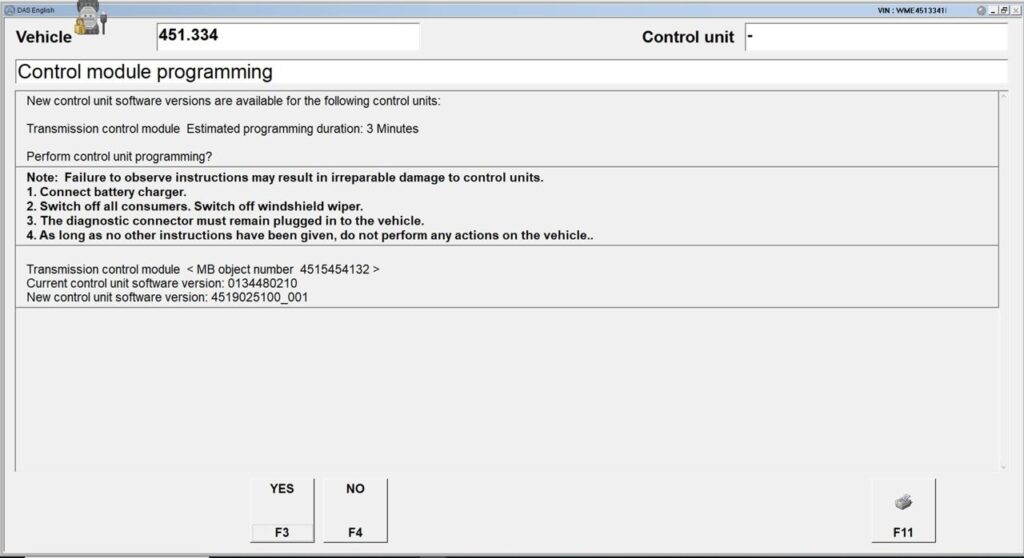

Upon encountering the P1700 code, we opted to inspect the module for software updates. While replacing the module is often considered, it’s typically unnecessary. Most issues can be resolved through a simple software update.

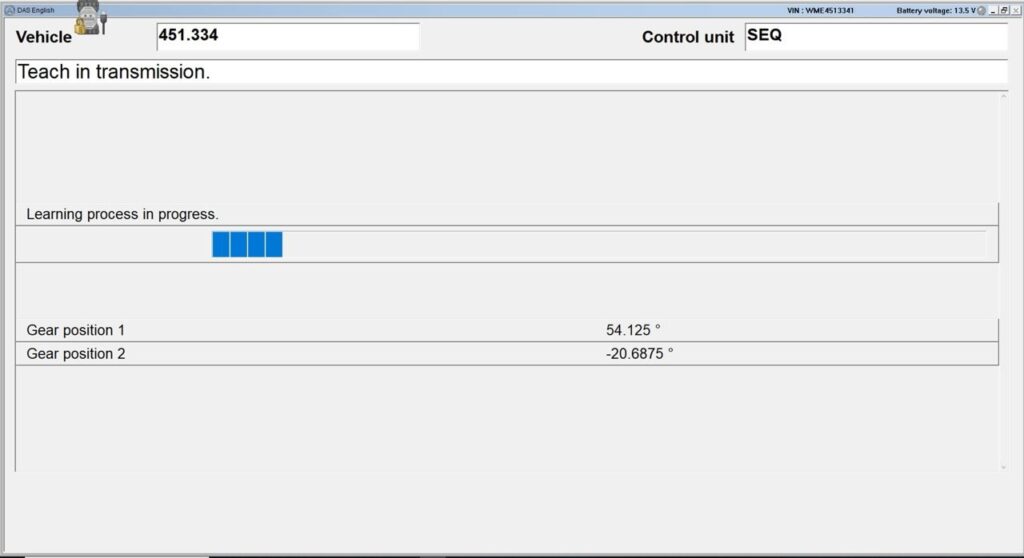

As depicted in the image above, an update was accessible, and we proceeded with its installation. Following the update of the “Sprintshift module,” it simply required a transmission relearning process.

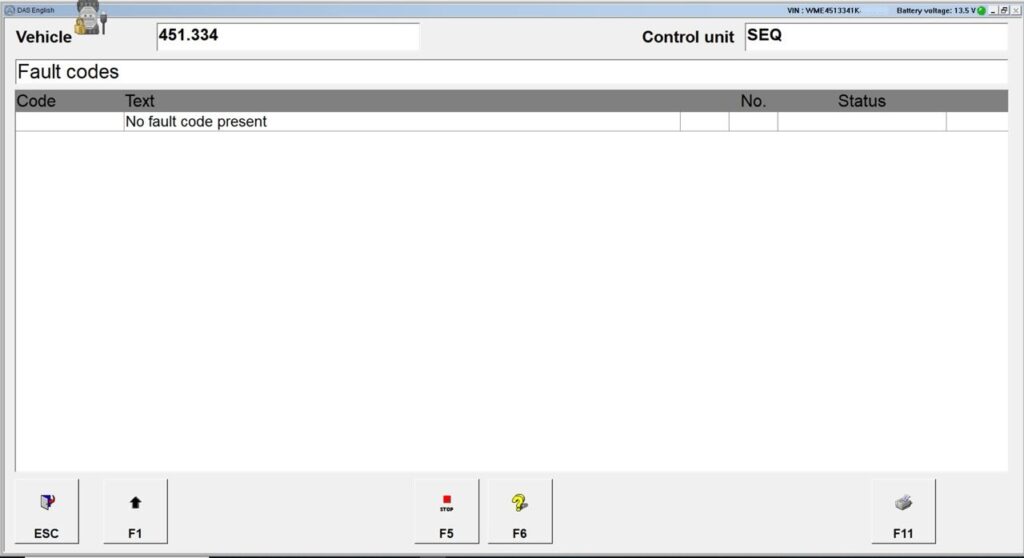

Reset fault codes and verify their absence to ensure they don’t resurface, allowing the customer to get back on the road with confidence.

What is Drag torque?

During gear shifts, synchronizing the speeds of the target gear and the supporting output shaft is crucial. This synchronization is facilitated by synchronization rings, which use friction to align the speeds of the components before engagement. However, the gearbox’s drag torque can disrupt this process by decelerating the input shaft. Consequently, this drag torque assists synchronization during up-shifts and opposes it during down-shifts.